Back to Basics….What is Metal Forming and Metal Processing

Metal stamping is a manufacturing process that involves cutting, forming, and shaping metal sheets into various parts and components. The process utilizes specialized equipment, such as stamping presses, dies, and tooling, to transform metal sheets into high-precision parts with minimal waste. The metal stamping process starts with a flat

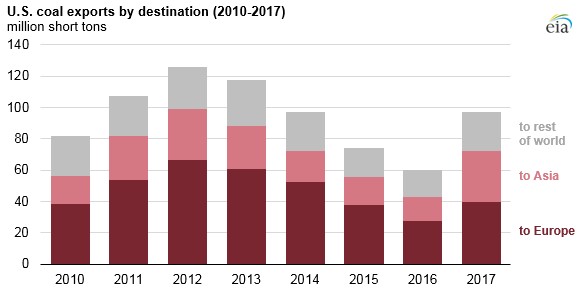

U.S. Coal Mining & Vulcan, Inc.

U.S. Coal Mining & Vulcan, Inc. We are going to stop regulations that threaten the future and livelihood of our great coal miners. – President Donald Trump In his first address to Congress, President Trump relayed the message that many Americans were excited to hear. After US coal production peaked

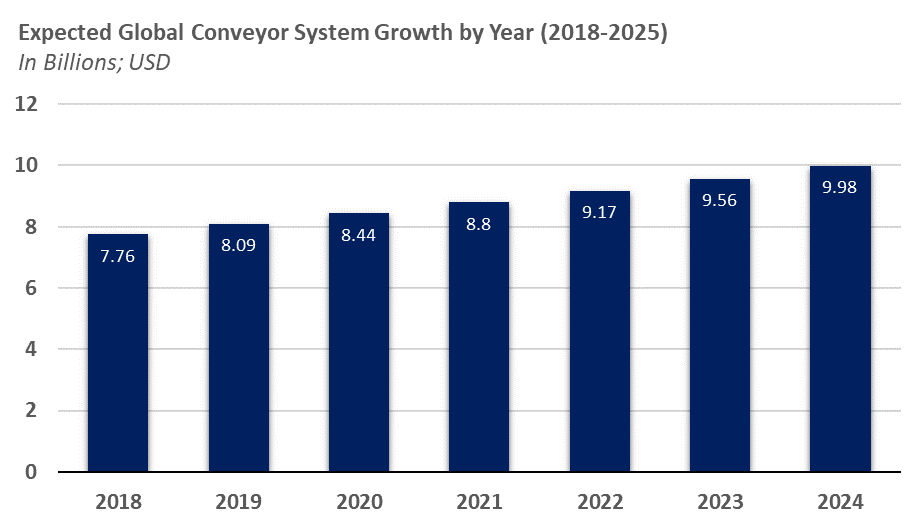

The Growth of the Global Conveyor Systems

The Growth of the Global Conveyor Systems The global conveyor system market is expected to grow to around $9.98 billion (USD) by 2025, at a growth rate just north of 4%. — Zion Market ResearchAccording to a report the global conveyor system market was valued at an estimated $7.45 billion

The Decay of US Infrastructure

The Decay of US Infrastructure America’s infrastructure is desperately in need of investment, according to the American Society of Civil Engineers. It’s estimated the US needs to spend around $4.5 trillion by 2025 to fix the country’s roads, bridges, dams, airports, and other infrastructure. — American Society of Civil Engineers